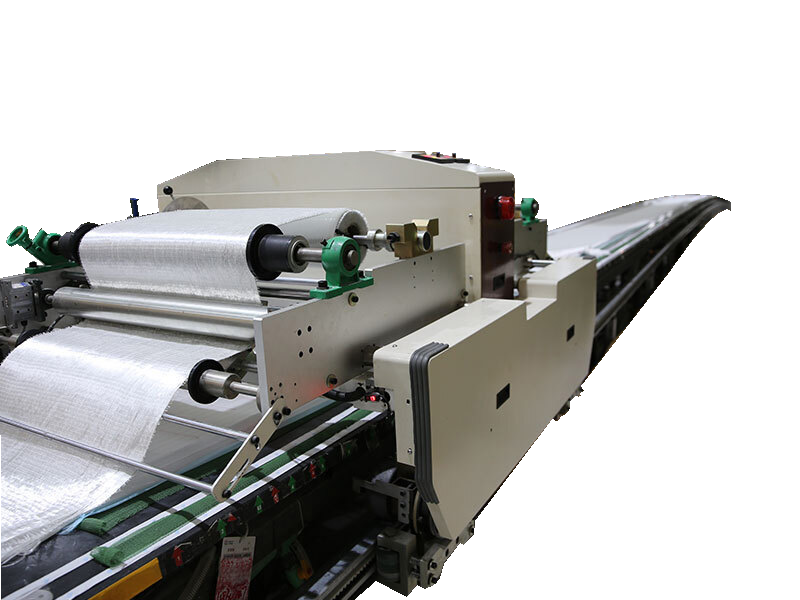

Intelligent root miller

智能端面铣床

It is used for milling the end face of the pre-embedded bolt sleeve of the wind power leaf root, which has the advantages of high machining precision, high efficiency, convenient positioning, safety, reliability and environmental friendliness, etc., and has been highly praised by the majority of customers. This equipment solves the big problem of leaf root end face processing, greatly improves the plane precision and production efficiency, is the first choice in wind power industry.

用于对风电叶根预埋螺栓套端面进行铣削加工处理,具有加工精度高,效率高,定位方便、安全可靠、环境友好等优点,受到广大客户的好评。

该设备解决了叶根端面加工的大难题,大大提升了平面精度及生产效率,是行业的首选。

It is used for milling the end face of the pre-embedded bolt sleeve of the wind power leaf root, which has the advantages of high machining precision, high efficiency, convenient positioning, safety, reliability and environmental friendliness, etc., and has been highly praised by the majority of customers.

This equipment solves the big problem of leaf root end face processing, greatly improves the plane precision and production efficiency, is the first choice in wind power industry.

1.加工精度高,平面加工精度最高达到0.12mm,远超同行业其他磨铣设备的精度;

High machining precision, the highest plane machining precision reaches 0.12mm, far exceeding the precision of other milling equipment in the same industry;

2.定位精度高,采用智能算法,自动寻找与叶根最佳的平行平面进行定位,加工余量最少;

High positioning accuracy, using intelligent algorithms, automatically find the best parallel plane with the leaf root for positioning, with minimum machining allowance;

3.安全性能高,内涨式定位,支撑腿具有载荷、位移及扭矩同时监控保护,定位安全可靠;

High safety performance, internal rise type positioning, support leg with load, displacement and torque monitoring and protection at the same time, positioning safety and reliability;

4.加工效率高,变频双主轴同时加工,效率较砂轮打磨提升5倍以上;

High machining efficiency, frequency conversion dual spindle simultaneous processing, efficiency is more than 5 times higher than grinding wheel grinding;

5.高精度自检,确保加工后的每一只叶片都是合格产品,为客户节省检测成本及时间;

High-precision self-inspection, to ensure that each blade after processing is a qualified product, saving inspection costs and time for customers;

6.数据可追溯,所有的测量数据及操作记录均按叶片的编号进行存储,方便今后统计查询;

Traceable data, all measurement data and operation records are stored according to the number of the blade, which is convenient for future statistical inquiries;

7.环境更友好,配备高效除尘系统,铁屑及粉尘清除效率高,现场卫生安全;

More friendly environment, equipped with high efficient dust removal system, high efficiency of removing iron chips and dust, on-site hygiene and safety;

8.兼容范围大,可以同时兼容几种不同节圆的叶片,切换速度快,降低设备采购成本;

Compatible with a wide range, can be compatible with several different pitch circle blades at the same time, fast switching speed, reduce equipment procurement costs;

9.专用型刀片,可以同时铣削螺栓套及玻璃钢,使用寿命长,耗材成本低;

Specialized blades can mill bolt sets and fiberglass at the same time, with long service life and low cost of consumables;

10.工作强度低,无需登高,即可以完成设备的吊装定位,并配备维修平台,维护方便;

Low work intensity, no need to ascend, that is, can complete the equipment lifting and positioning, and equipped with maintenance platform, easy maintenance;

11.维护成本低,只需定期清扫并涂抹润滑脂即可;

Low maintenance cost, only need to clean and grease regularly;

12.可自动行走,搭配电动堆垛机,移动方便;(选配)

Automatic walking, with electric stacker cranes, easy to move; (optional)

13.信息化管理,可以远程监控设备的使用状态,查询处理数据信息,实现信息化管理。(选配)

Informatization management, can remotely monitor the use status of the equipment, query processing data information, realize informatization management. (Optional)

技术参数表 Technical parameter table

|

序号 NO.

|

项目名称 Project

|

型号及技术指标 Model and technicalities |

|||||

|

EFMM-ⅠA |

EFMM-ⅡB |

EFMM-ⅢD |

EFMM-ⅣA |

EFMM-ⅤA |

EFMM-ⅤIB | ||

|

1 |

适用叶片节圆规格(mm) Applicable specification of blade pitch |

Ф1800~Ф2300 |

Ф2300~Ф2800 |

Ф2800~Ф3200 |

Ф3200~Ф3600 |

Ф3600~Ф4600 |

Ф4600~Ф6000 |

|

2 |

平面加工精度(mm) Plane machining accuracy |

0.15~0.25 |

0.20~0.35 |

0.25~0.40 |

0.30~0.40 |

≤0.50 |

≤0.50 |

|

3 |

主轴径向进给调节范围(mm) Spindle radial feed adjustment range |

0~400 |

0~400 |

0~300 |

0~300 |

0~500 |

0~700 |

|

4 |

主轴轴向进给调节范围(mm) Spindle axial feed adjustment range |

0~50mm |

|||||

|

5 |

加工主轴功率 Spindle power |

3kW |

|||||

|

6 |

铣刀盘直径(mm) Maximum of diameter of milling cutter head |

Ф125mm~Ф200mm |

|||||

|

7 |

最大回转速度 Maximum speed of rotation |

1rpm |

|||||

|

8 |

最大回转角度 Maximum angle of rotation |

≥400° |

|||||

|

9 |

表面加工粗糙度 Surface finish |

≤Ra1.6 |

|||||

|

10 |

电源 Power supply |

3×400VAC+N+PE |

|||||

|

11 |

涨紧压力显示 Tension pressure display |

选配 Optional |

选配 Optional |

标配 Standard |

标配 Standard |

标配 Standard |

标配 Standard |

|

12 |

变频双主轴加工系统 Variable frequency double spindle machining system |

选配 Optional |

选配 Optional |

标配 Standard |

标配 Standard |

标配 Standard |

标配 Standard |

|

13 |

自动微调系统 Automatic trimming system |

选配 Optional |

选配 Optional |

标配 Standard |

标配 Standard |

标配 Standard |

标配 Standard |

|

14 |

高效集尘系统 High efficiency dust collecting system |

选配 Optional |

选配 Optional |

标配 Standard |

标配 Standard |

标配 Standard |

标配 Standard |

|

15 |

设备重量 Machine weight |

2400Kg |

3600 Kg |

4500 Kg |

5600 Kg |

7000 Kg |

8100Kg |

关注我们

关注手机端

关注微信公众号

Copyright©湖南优发国际智能装备有限公司 All rights reserved 湘ICP备2021000766号 本网站支持IPV6

网站建设:中企动力 长沙

Copyright©湖南优发国际智能装备有限公司

湘ICP备2021000766号

网站建设:中企动力 长沙